Easily Manage All Your Business Processes

CoralReef MES is a MES system that enables you to manage all processes from raw material entry to shipment and manage all your production resources with complementary modules such as detailed scheduling, maintenance, mold / tooling, operational quality, inventory management, and can work with minimum data input of people, mainly by collecting data from machines.

CoralReef MES is involved in the MES Product Survey conducted by CGI. It is a leading brand in Turkey.

Properties

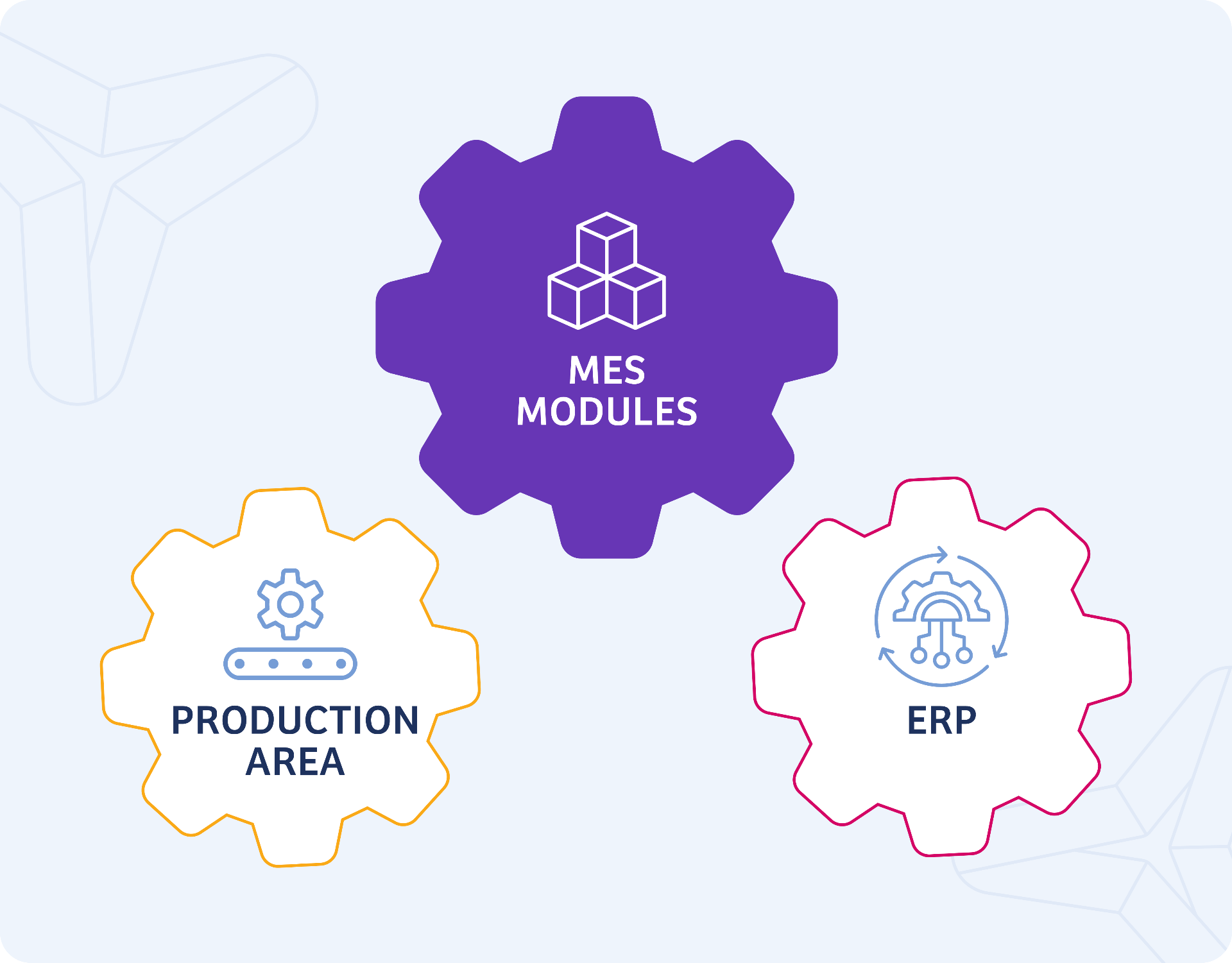

You can be integrated independent from ERP.

Your data entry topology and data collection topology can be fully realized independent from trademark-model.

A full integration with barcode, data matrix, RFID and similar technologies are possible.

Reporting-dashboard and Andon modules are completely Web Based.

You can set up a notification system with unlimited mail / SMS according to the determined workflow.

You can generate reports on mobile phones and / or PCs (IOS and Android OS supported). You can access data such as PPM, OEE, and posture analysis with mobile mediums. You can report on the web (Explorer, Chrome, Firefox, Yandex, etc.).

You can monitor the production status via andon screens while you are in the production area.

Our Statistics

Workflow

This is the section where maintenance and malfunctions are managed.

- Tracking malfunctions,

- Monitoring malfunction response times and consumables used in malfunctions,

- Opening malfunction work order and informing by e-mail,

- Equipment maintenance monitoring,

- Integration of planned maintenance activity inputs and machine programming,

- Follow-up of planned maintenance activities instructions,

- Tracking of MTBF, MTBR reports.

This is the section where the process tracking of molds and tools is managed.

- Time-based tracking of mold / tool life,

- Quantity based mold / tool life tracking,

- Mold / tool location tracking,

- Following maintenance instructions and monitoring maintenance time-cost,

- Tracking of the mold / tool assembly-disassembly process.

It is the module where the subcontractors and the processes of the suppliers can be monitored.

- Login via own user name and password by the users and printing labels out,

- Quick acceptance of printed labels by scanning,

- Suppliers can enter the delivery bills over the system,

- Subcontractors have access to their work orders over the web and production entry,

- Monitoring the stocks of products shipped to Subcontractors,

- Direct material acceptance via entry and approval of production notification by subcontractors.

It is the module determining which job, in which order, on which machine is going to be performed.

- Work schedule entry,

- Overtime entry,

- Creating production plan on daily-weekly-monthly basis,

- Planned-actual production values analysis,

- Machine and work line occupancy rates analysis,

- Analysis of capacity occupations (based on time),

- Monitoring of production plan revisions and monitoring of differences,

- Graphical machine programming (gannt chart),

- Unplanned work tracking and drag-and-drop machine programming,

- Batch shift in case of change of plan.

It is the module that provides the traceability of processes by collecting automatic and manual data from the production unit.

-

The production quantity, production stop information and operation-control criteria and similar information realized in the workshop area during production will be automatically received through the machines via PLCs or sensors.

-

Data entry can be made with data collection devices to be installed in the machines according to the project type.

It is the module that provides the traceability of processes by collecting automatic and manual data from the production unit.

-

The production quantity, production stop information and operation-control criteria and similar information realized in the workshop area during production will be automatically received through the machines via PLCs or sensors.

-

Data entry can be made with data collection devices to be installed in the machines according to the project type.

It is the module in which material requirement planning and main production plan are created.

- Automatic creation of purchase orders to meet orders,

- Automatic generation and revision of required production orders,

- Parametric warehouse (s) selection,

- Create purchase order or production order according to lot sizes,

- MRP / MPS calculation options by day, week, month

- Possibility to calculate MRP / MPS according to safety tolerances.

It is the module where product configuration can be monitored and the flexible entry of orders can be done.

- Flexible route-recipe creation according to feature set and values,

- Flexible and easy order entry,

- Automatic generation of source information after order entry and approval stage without recipe and route creation.

It is a module that provides personnel tracking in integration with PDKS devices.

- Integration with different Personnel Attendance Tracking Systems with SQL Database,

- Personnel work-entry and exit monitoring,

- Personnel-based OEE analysis.

It is the module that transfers the BOM (Bill ofMaterials) to the systems with PLM software and drawing programs.

- BOM (Bill ofMaterials) and route integration with PLM software,

- Stock cards integration,

- Product parameters integration.

It is the module that allows the enterprise to transfer orders from the OEM’s to the existing ERPs.

- Order - delivery note integration with OEM’s,

- Integration with MT940 and similar standards,

- Automatic data transfer to ERPs.

It is the module where service processes can be monitored

- Work order management for the works coming to the service,

- Service spare parts tracking,

- Tracking the service forms of the service,

- Service personnel monitoring,

- Traceability of technical drawings, delivery notes, pictures and similar documents related to the products arriving at the service,

- Traceability of service, purchasing-sale processs of service spare parts.

The main objective is to focus on minimizing losses and reducing costs.

It is aimed to manage the performance of the resources via MES system.

Our main resources are: Machinery, Personnel, Inventory

The CoralReef MES system aims to manage variously all resources by tracking the personal and inventory and not only the machinery performances.

Reporting

The reporting tool, along with dashboard and other analysis tools, allows for the design and monitoring of unlimited statistical reports from the system.

All screens can be customized by users, and user-specific screens can be created without any coding knowledge. An unlimited number of reports and analyses can be created as custom dashboards. Consolidated reports can be generated by integrating with ERP and other software systems.

Sample Reports that can be obtained with CoralReef:

- Failure Frequency Reports

- Maintenance Management Reports

- Employee Performance Reports

- Downtime Analysis and Error Reports

- Scrap and Waste Analysis Reports

- Capacity Utilization Reports

- Standard vs. Actual Comparison Reports

- OEE, PPM Reports

- Planning Performance Reports

- Recipe Usage Comparison Reports

- MTTR, MTBR, MTBF Reports

- Traceability Reports

- Productivity Analysis

Download Document

Frequently Asked Questions

In which sectors can CoralReef MES be used?

CoralReef MES can be used independently across various sectors such as defense, aviation, automotive, food, energy, pharmaceuticals, plastics, metals, textiles, furniture, and electrical-electronics.

What is the installation process of CoralReef MES?

CoralReef MES is a solution that can be customized according to the customer's business processes and production infrastructure. The installation duration can vary depending on the customer's requirements.

What are the reporting capabilities offered by CoralReef MES?

CoralReef MES provides detailed reporting capabilities across various areas such as production, performance, quality, maintenance, and more. It supports decision-making processes for managers.

How does CoralReef MES integrate with ERP systems?

CoralReef MES can integrate with ERP systems in an independent manner. By exchanging data with the customer's existing ERP system, it enables the management of production processes in a way that is compatible with the ERP. This allows you to protect your ERP investment while increasing production efficiency.

How is productivity tracked with CoralReef MES?

CoralReef MES collects real-time data from each machine on the production lines. Thanks to this data:

- Key performance indicators (KPIs) such as production quantities, production hours, downtime durations, and scrap rates can be monitored in real-time.

- Bottleneck analysis can identify problematic points in the production flow.

- Machine and labor efficiencies can be measured.

- Production planning and scheduling optimization can be achieved.

This enables the instant and detailed monitoring, reporting, and improvement of production performance. Managers can make fast and effective decisions based on the detailed efficiency analyses provided by CoralReef MES.

What database systems can work with CoralReef MES?

CoralReef MES can work in compatibility with various database systems:

- Microsoft SQL Server

- Oracle Database

- MySQL

- PostgreSQL

How are orders entered into CoralReef MES?

Orders can be entered into CoralReef MES in various ways:

Manual Order Entry: Orders can be manually entered one by one through the user interface of CoralReef. All order details such as customer information, product details, quantities, and delivery dates can be transferred to the system this way.

Automatic Transfer via ERP Integration: Data integration can be established between the company's ERP system (such as Logo, Netsis, SAP, Oracle) and CoralReef MES. This way, orders created in the ERP are automatically transferred to CoralReef.

File Upload: Customer order information in files such as CSV or Excel can be uploaded to CoralReef. The system reads these files and automatically creates the orders.

Can bills of materials (BOMs) be defined in CoralReef MES?

CoralReef MES allows the definition of product recipes (BOMs). The main features are:

Product structure: Definition of sub-components, raw materials, and semi-finished products for each product.

Multi-level recipe support: Complex product recipes with multiple levels can be created.

Revision management: Changes made to recipes can be easily tracked.

Alternative components and quantities: Different alternatives and quantities can be specified for a component.

Units and measurement units: Different measurement units (kg, pcs, etc.) can be used for each component.

This way, CoralReef MES ensures the correct procurement and usage of raw materials, semi-finished goods, and components required in the production processes. Through recipe management, production costs can also be effectively controlled. It can be integrated with the ERP system for effective management.

Why should we use CoralReef MES in addition to our existing ERP system?

Flexible and Easy-to-Use Customizable Screens: CoralReef MES allows customization of user interfaces, enabling flexible and easy-to-use screens.

Production-Centric: CoralReef MES focuses more deeply and has advanced features for production processes, while ERP systems are designed for more general business management.

Real-Time Production Visibility: CoralReef provides comprehensive production visibility by tracking every step in the production line and machine data in real-time.

Reporting Flexibility: CoralReef offers more customizable and detailed reporting capabilities on production performance, quality, machine efficiency, and more.

Advanced Production Planning: CoralReef's advanced planning and scheduling capabilities can make the planning processes in the ERP system more accurate and efficient.

Industry 4.0 Compatibility: CoralReef is more aligned with smart factory and Industry 4.0 applications.

For these reasons, using CoralReef MES in addition to the ERP system provides a more holistic, visible, and efficient approach to production management.

Customer Feedback

Contact Us

Would you like to get more detailed information about İletişim Yazılım?